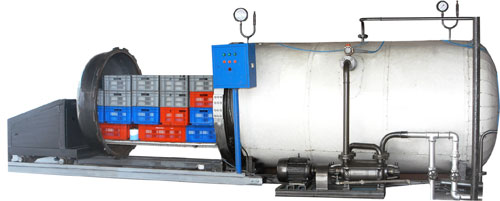

Each production step like spinning, twisting or knitting causes tension in yarn & fibre. Yarns tend to snarl in order to relax. Tension and snarling lead to problems in downstream processing. Blue moon yarn steaming autoclaves provides optimal and smooth treatment for following application.

| Data | BM 150 | BM 300 | BM 500 | BM 800 | BM 1000 |

| Capacity (Kgs./Batch) |

150 | 300 | 500 | 800 | 1000 |

| Area required (W x L x H) (Meter) | 3 x 7 x 2.3 | 3 x 8 x 2.3 | 3 x 9 x 2.3 | 3.5 x 8 x 2.6 | 3.5 x 9 x 2.6 |

| Heating Source | Elect. Heater /Steam Boiler/Thermic Oil Heater | ||||

| Working Temperature | 65° C to 150° C | ||||

| Working Pressure | -700 mm Hg to 42 PSI (3 kg/cm2) | ||||

| Method of Loading | Auto Loading | ||||

| Method of Locking | Auto Locking | ||||

| Vacuum System | vacuum pump to achieve 700 to 720 mm Hg | ||||

| Material Of Construction | C. S. | ||||