An ideal machine for low ceiling height. You do not require more than 3 mtrs. height hence installation cost is low compared to conventional vertical dyeing machine. Thanks to the design concept, there is no need of hoist for loading spindles. It can easily be done manually. Even the foundation is very simple and the machine can be installed at floor level.

| Model | Capacity* Kgs. | Pump Kw | Work Space (meters) | ||

| Length | Width | Height | |||

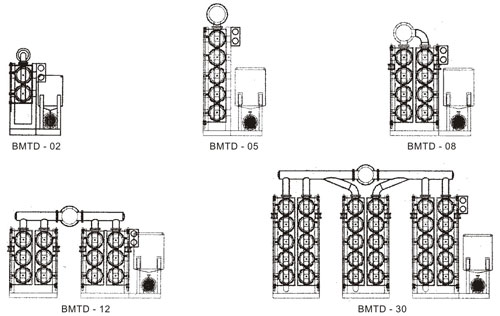

| BMTD 01 | 20 | 3.7 | 6.0 | 1.0 | 1.8 |

| BMTD 02 | 40 | 3.7 | 6.0 | 1.0 | 1.8 |

| BMTD 03 | 60 | 5.5 | 6.0 | 1.0 | 1.8 |

| BMTD 04 | 80 | 7.4 | 6.5 | 1.0 | 2.2 |

| BMTD 05 | 100 | 9.3 | 7.0 | 1.0 | 2.5 |

| BMTD 06 | 120 | 11 | 7.0 | 1.5 | 1.8 |

| BMTD 08 | 160 | 11 | 7.0 | 1.5 | 2.2 |

| BMTD 10 | 200 | 15 | 7.0 | 1.5 | 2.5 |

| BMTD 12 | 240 | 18.5 | 7.5 | 2.75 | 1.8 |

| BMTD 16 | 360 | 22 | 7.5 | 2.75 | 2.2 |

| BMTD 20 | 400 | 22 | 8.0 | 2.75 | 2.5 |

| BMTD 24 | 480 | 30 | 8.0 | 4.0 | 2.5 |

| BMTD 30 | 600 | 37 | 8.0 | 4.0 | 2.8 |