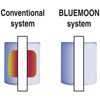

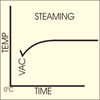

Cold saturated steam is produced at low temperature (46-48°c) by indirect steaming system and by maintaining vacuum pressure in vessel, This is mandatory for gentle process and even steam penetration.

Exhausts all air from cone

Evenly penetrates in to the yarn.

At constant temp. yarn gets conditioned homogeneously.

Exhausts all gases & steam from the machine.

For homogeneous yarn quality

No condensate spots

Vacuum helps to produce cool saturated steam at low (48° C) temp.

Short & Energy Efficient Treatment Time

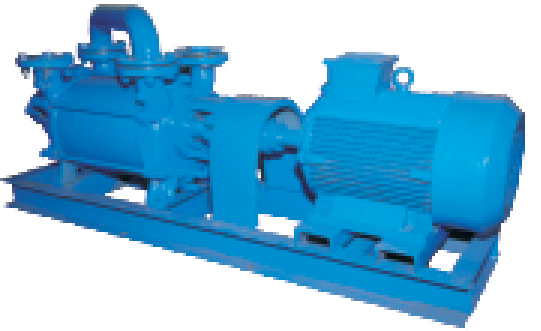

Double stage low speed pump with higher exhaust volume & low maintenance

Touch Screen operator front panel with PLC for Precise repeatability.

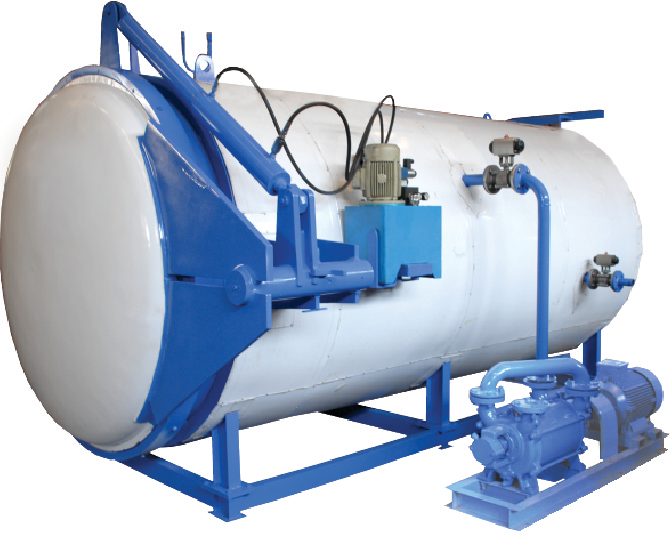

| Data | BM 500 | BM 800 | BM 1000 | BM 1500 |

|---|---|---|---|---|

| Capacity (Kgs./Batch) |

500 | 800 | 1000 | 1500 |

| Diameter of Vessel (Meter) |

1.6 | 1.6 | 1.6 | 2 |

| Usable length (Meter) |

2.5 | 3.5 | 4.5 | 4.5 |

| Overall Diameter of M/c. (Meter) |

2.1 | 2.1 | 2.1 | 2.6 |

| Overall Length of M/c. (Meter) |

4 | 5 | 6 | 6 |

| Overall height of M/c. (Meter) |

2.1 | 2.1 | 2.1 | 2.6 |

| Area required (W x L X H) (Meter) |

5 x 9 X 4 | 5 x 10 X 4 | 5 x 12 X 4 | 5 x 15 X 5 |

| Connected Load (Elect.Heater) | 72 KW | 96 KW | 108 KW | 144 KW |

| Connected Load (Vacuum System) | 5.5 KW | 7.5 KW | 11 KW | 11 KW |

| Heating Source | Electric Heating Coils / Steam Boiler / Wood fired / Thermic Oil Heater | |||

| Working Temperature | 46° C to 135° C | |||

| Working Pressure | 700 mm Hg to 40 PSI (2.7 kg/cm2) | |||

| Method of Loading | Mechanized | |||

| Method of Locking | Hydraulic | |||

| Vacuum System | vacuum pump to achieve 700mm Hg, upto 750 mm Hg | |||

| Material Of Construction | S.S. 304 | |||